FKgroup: SETTING SAIL FOR PRECISION AND INNOVATION IN MARINE FABRIC CUTTING

FKgroup

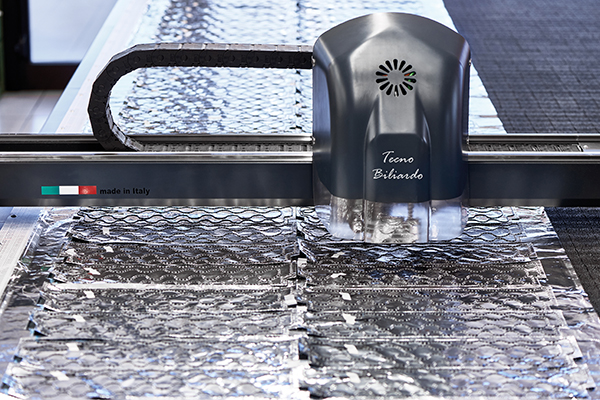

Thanks to their high-performance characteristics, composite materials are used extensively in the marine sector, but their use requires special precautions in the production of hulls, decks and boat superstructures.

One of the stages that determines the result is definitely the cutting process, the companies involved must set up the cutting room following some tricks to achieve satisfactory results in terms of product quality and cost sustainability.

What features should a cutting room for the marine sector have?

Versatility: possibility of cutting different types of material with different weights

Flexibility: adaptability to more or less intense production volumes.

Speed: to reduce the process time. Multilayer cutting can greatly help to reduce the time required, as long as it does not overstress the tissue.

Precision: each cut must be calibrated and ensure millimetric accuracy.

Different types of blades: any good cutting room must have a wide variety of blades, perhaps even tailored to each specific project.

Temperature control: the machines must be equipped with systems that allow cold cutting, which is indispensable when cutting prepregs that risk polymerizing when the temperature rises.